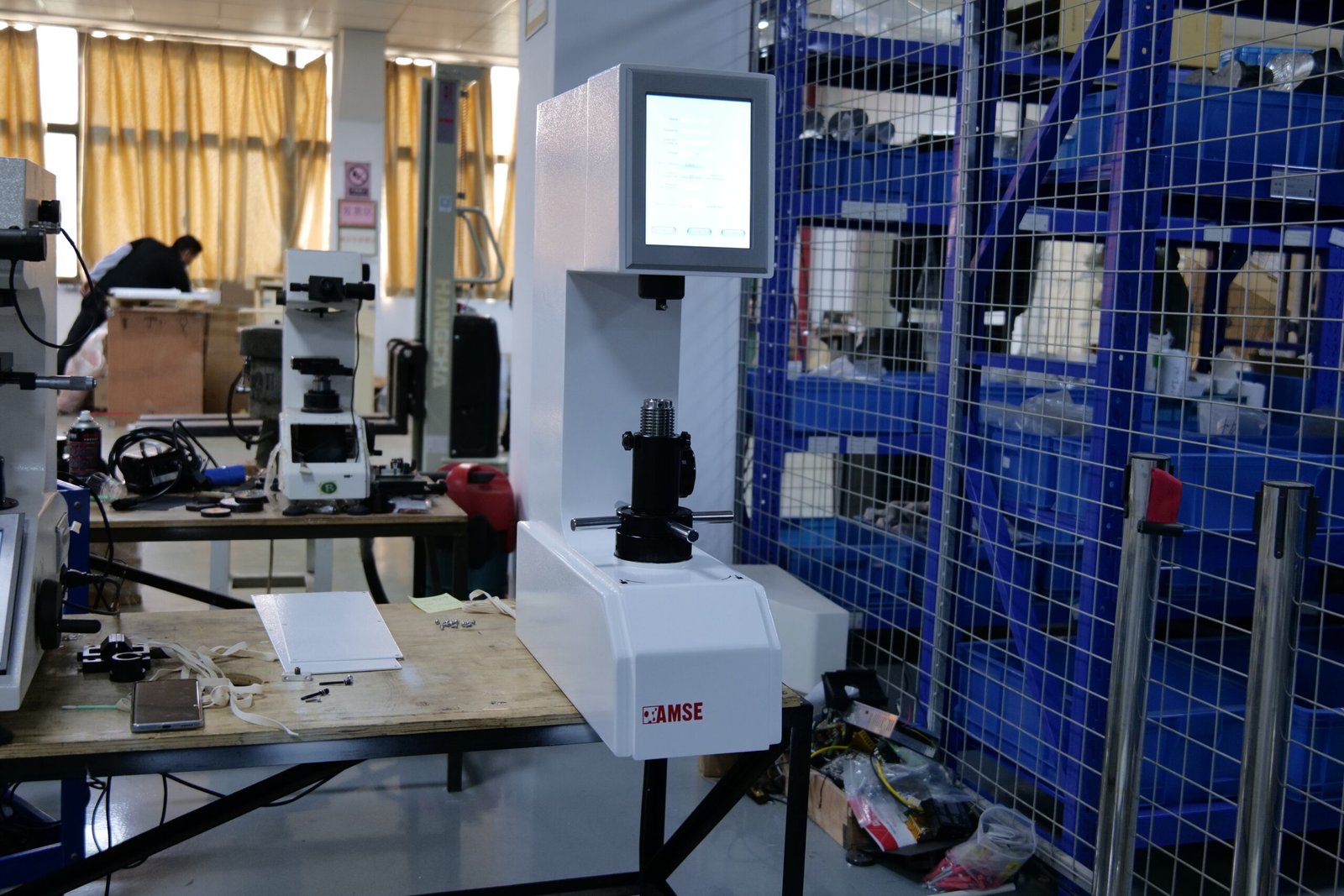

Material hardness is a fundamental property that determines its resistance to deformation. We offer cutting-edge solutions for hardness measurement. These precision instruments are ideal for accurate analysis of metals and other materials, providing essential data for quality control and research.

The durometers are distinguished by their precision and versatility, allowing measurements to be taken according to the main test methods:

How They Work:

The basic operation of a durometer involves:

Applications:

Shimadzu durometers are used in various sectors, including:

For more information about this product, fill out the online form below

"*" indicates required fields

Strada della Cebrosa 86

10156 Turin (TO) – Italy

Contact us to get the details of our local agent closest to your location.

MEPA – The Italian Public Administration Electronic Marketplace

"*" indicates required fields