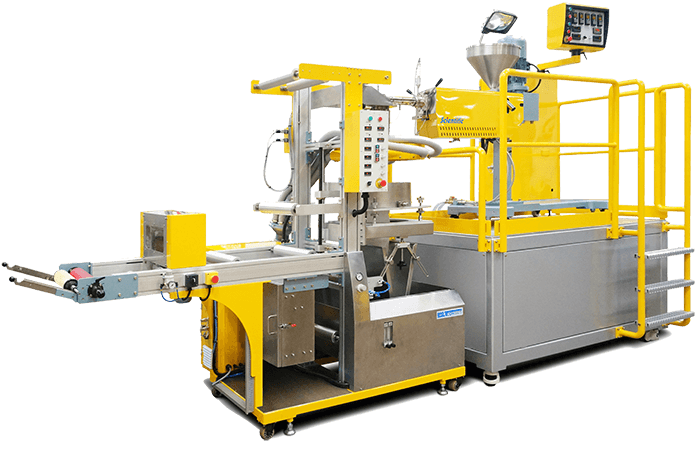

The downward blown film line utilizes a water-cooling system for the bubble, which allows for rapid cooling of the melt coming out from the die. This process accelerates the solidification of the film, particularly improving the transparency and gloss of the final product.

This technology is especially effective in processing polypropylene (PP), a material notoriously difficult to manage with traditional air-cooling methods. Thanks to water cooling, PP can be blown with greater ease, resulting in high-quality films with an excellent visual appearance. Unlike classic up-blown air cooling, this system significantly reduces the processing difficulties associated with PP and other complex or slow-cooling sensitive resins.

This technology represents an ideal solution for manufacturers who require high aesthetic film quality and flexibility in material selection.

| Linea per film in bolla verso il basso // Water Quenching film blowing line | LWQF-400 |

|---|---|

| Larghezza massima del film // Max lay flat width (mm) | 300 |

| Velocità massima // Max Film speeds (m/min) | 40 |

| Output con estrusore 25mm // Max output with 25 mm. extruder (kg/h) | 10 |

| Altezza filiera / Nip-Roll // Height from die to Nip-Roll (mm) | 1215 |

| Altezza torre // Total height of film tower (mm) | 2.500 |

| Potenza elettrica totale // Total electrical power (kW) | 8,7 |

| Diametro del labbro filiera // Die lip diameter (mm) | 350 |

For more information about this product, fill out the online form below

"*" indicates required fields

Strada della Cebrosa 86

10156 Turin (TO) – Italy

Contact us to get the details of our local agent closest to your location.

MEPA – The Italian Public Administration Electronic Marketplace

"*" indicates required fields